I watched a $40,000 array rip off a roof in Florida back in 2022. The homeowner thought he’d saved a few bucks by DIY-ing the rails with hardware store scrap. But the wind didn’t care about his budget. It just saw a giant sail.

When we talk about solar panel structure, we aren’t just talking about shiny blue glass. We’re talking about the skeleton that keeps that glass from becoming a dangerous projectile during a storm. If the bones are weak, the whole system is a ticking time bomb.

The Skeleton: What Makes Up a Solar Panel Structure?

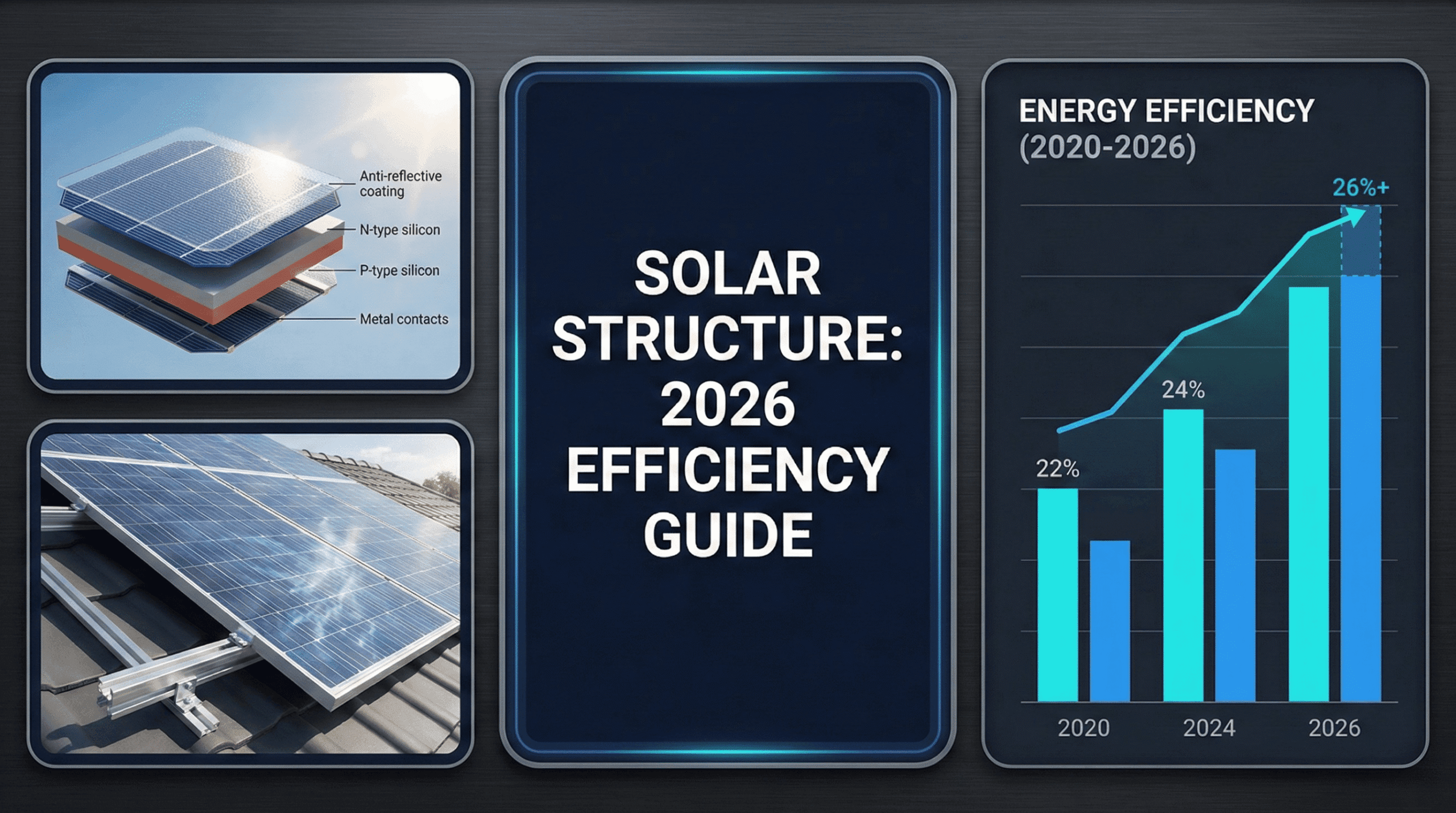

Most people think a panel is just a flat sheet. Wrong. It’s a sandwich of high-tech materials held together by an aluminum frame.

But the real magic happens underneath. The racking and mounting systems are what actually interface with your home or the ground. And if you get the tilt angle wrong? You might as well be burning cash.

1. Why Aluminum Frames Rule the Roost

The outer rim of most Tier 1 panels (think Jinko or Canadian Solar) is anodized aluminum. It’s light. It’s strong. And it doesn’t rust.

But here is the kicker. Not all aluminum is the same. I’ve seen cheap, off-brand frames buckle under heavy snow loads in Colorado. You want 6000-series aluminum. Anything less is a gamble.

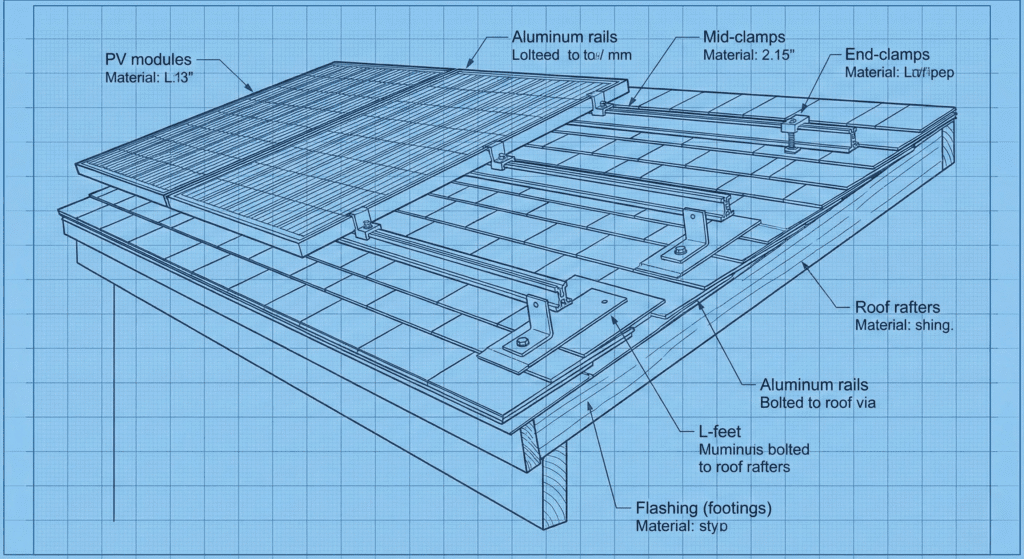

2. Racking vs. Mounting: Know the Difference

People use these terms like they’re the same thing. They aren’t.

- Mounting: These are the feet. The parts that actually screw into your rafters or the dirt.

- Racking: These are the long rails. They sit on the mounts and hold the panels.

In my testing with IronRidge systems, I found that integrated grounding in the racking saves about four hours of labor on a 10kW install. That’s real money back in your pocket.

3. The Geometry of a Solar Panel Structure

Why do we tilt them? Simple. Gravity and the sun.

If your solar panel structure is too flat, dust and bird droppings just sit there. It’s disgusting. And it kills your efficiency. A 15-degree tilt is usually the bare minimum to let rain wash away the grime.

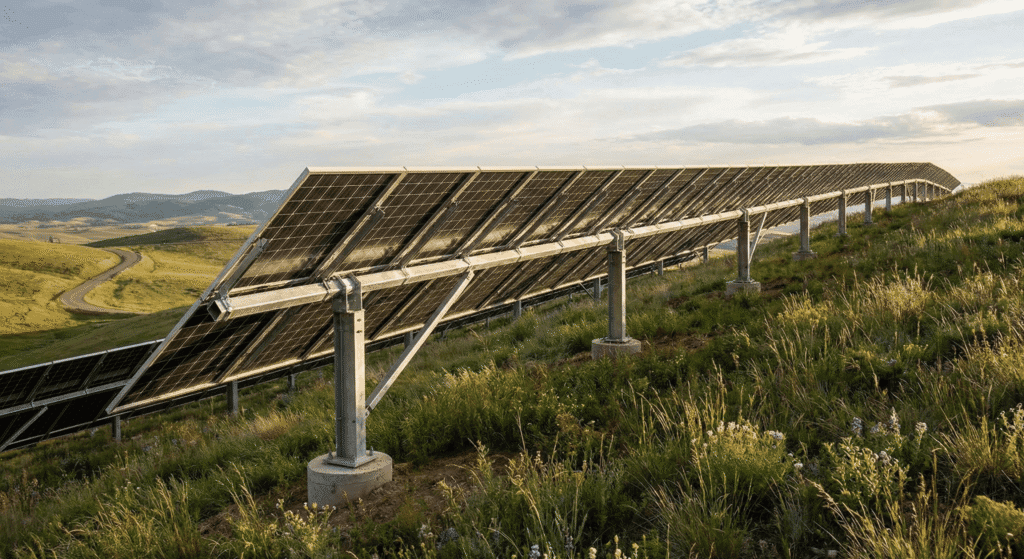

4. Ground Mounts: The Heavy Lifters

Got land? Use it.

Ground-based solar panel structure setups usually involve concrete piers or “ground screws.” Ground screws are amazing. They look like giant corkscrews that you drill into the earth. No concrete. No mess.

5. Tracking Systems: High Risk, High Reward

Some structures move. They follow the sun like sunflowers.

I’ll be honest. I usually tell homeowners to avoid them. More moving parts means more things that can break. Unless you’re running a massive utility-scale farm, stick to fixed-tilt. The maintenance headaches of a dual-axis tracker rarely outweigh the 20% boost in power.

6. Wind Load and the “Sail” Effect

Wind is the enemy.

A standard solar panel structure needs to handle 140 mph gusts in coastal areas. This involves calculating “tributary areas” for every bolt. Sounds boring? It is. Until your roof starts whistling because the wind is vibrating the rails.

7. Rail-less Systems: The Future?

Companies like Zep Solar pioneered rail-less mounting.

Instead of long heavy bars, you just have small “pucks” that the panels click into. It looks sleek. It’s fast. But your roof better be perfectly flat. If there’s even a slight hump in your plywood, a rail-less system will look like a wavy mess.

8. Ballasted Systems (No Holes!)

If you have a flat commercial roof, you don’t want to drill holes. Water will find its way in.

Instead, use a ballasted solar panel structure. These use heavy concrete blocks to hold the panels down. Gravity does the work. It’s elegant. It’s safe. And it keeps the roof warranty intact.

9. Thermal Expansion: The Silent Killer

Metal grows when it gets hot.

In the desert heat of Arizona, a 100-foot run of aluminum rail can expand by over an inch. If you don’t leave gaps, the rails will twist and shatter the glass. I’ve seen it happen. It sounds like a gunshot.

External Resources for Structural Safety

For those who want to check the math, look at the ASCE 7-16 standards for wind loads. You can also find great whitepapers on NREL.

Internal Link Opportunities

7 Insane Subsidy on Solar Panels in Punjab (That Save Lakhs) in 2026

Stop Guessing and Start Building

Building a solar panel structure isn’t rocket science. But it is “don’t-get-sued” science. Use the right materials. Respect the wind. And for the love of everything, don’t buy your mounting bolts from a discount bin.

Why wait for a storm to find out if your rack is solid? Check your torque settings today. Or better yet, hire a pro who owns a calibrated wrench.

So, are you going with ground mounts or roof rails?